How to Speed Up 3D Printing to Get More 3D Items Fast?

Share

3D printing is a powerful tool for creating everything from small toys to complex parts. But one common frustration is how long it takes to finish a print.

Waiting hours—or even days—can slow down projects and increase costs.

If you want to save money or print faster, you're in luck. There are many hardware and software options to make 3D printing faster while still ensuring a successful print. Let's look at some of them.

1. Choose the Right Nozzle Size

One of the best ways to make your 3D printing faster is by increasing the nozzle size.

The nozzle is the part that squirts out the plastic.

A bigger nozzle (like 0.8mm instead of 0.4mm) pushes out more plastic at once, so each layer takes less time. But this makes small details (like text or tiny parts) look rougher. Use a bigger nozzle only for simple shapes where details aren’t important.

2. Adjust Slicer Settings to Save Time

Your 3D design software (often called a “slicer”) controls how the printer moves. Here’s how to tweak it for speed:

Raise the Speed Setting

Most printers can handle 60–100 mm/s for basic objects. For simple shapes like a cube, try up to 150 mm/s—but test first! Too-fast speeds can leave rough edges or messy layers.

Move Quicker

The printer’s acceleration (how fast it starts and stops) and jerk (small sudden moves) can also be adjusted. Increasing these lets the printer zip between layers without slowing down too much. But don’t push it too far—sudden movements might cause mistakes.

Thicker Layers

Layers are the thin “slices” that build your object. Using thicker layers (like 0.3mm or 0.4mm instead of 0.1mm) means fewer layers overall. This cuts time but makes the surface less smooth, so save thicker layers for simple projects like prototypes.

3. Print Less to Print Faster

The less material your printer needs to put down, the faster it’ll finish. Here’s how to do it:

Simplify the Inside

The “infill” is the material inside your print. Most objects don’t need a solid core—it’s just extra time and plastic. Use simple internal patterns like straight lines or grids (instead of fancy spirals). For lightweight models, set the infill to 10–20% (like a hollow frame). For sturdier parts, 30–50% works well.

Reduce Supports When Possible

Supports are temporary structures that hold up overhanging parts of your print. They add time and waste material. Try redesigning your model to avoid steep angles, or use the software to make supports thinner and less dense. This cuts down on cleanup and printing time.

Skip the Base

Rafts (thick bases under the print) are often unnecessary. Only use them if your printer struggles to stick to the build plate.

Use Symmetrical Shapes

Symmetrical designs let the printer repeat patterns, saving time. For example, a symmetrical vase takes half the time of an asymmetrical one.

Optimize Wall Thickness

The outer walls of your print affect speed. Thicker walls (0.8mm or more) take less time to print but may look chunkier. Thin walls (0.4mm) are slower but smoother for detailed objects.

Upgrade Your 3D Printer if You Print Often

Buying a faster printer or upgrades can save hours over time.

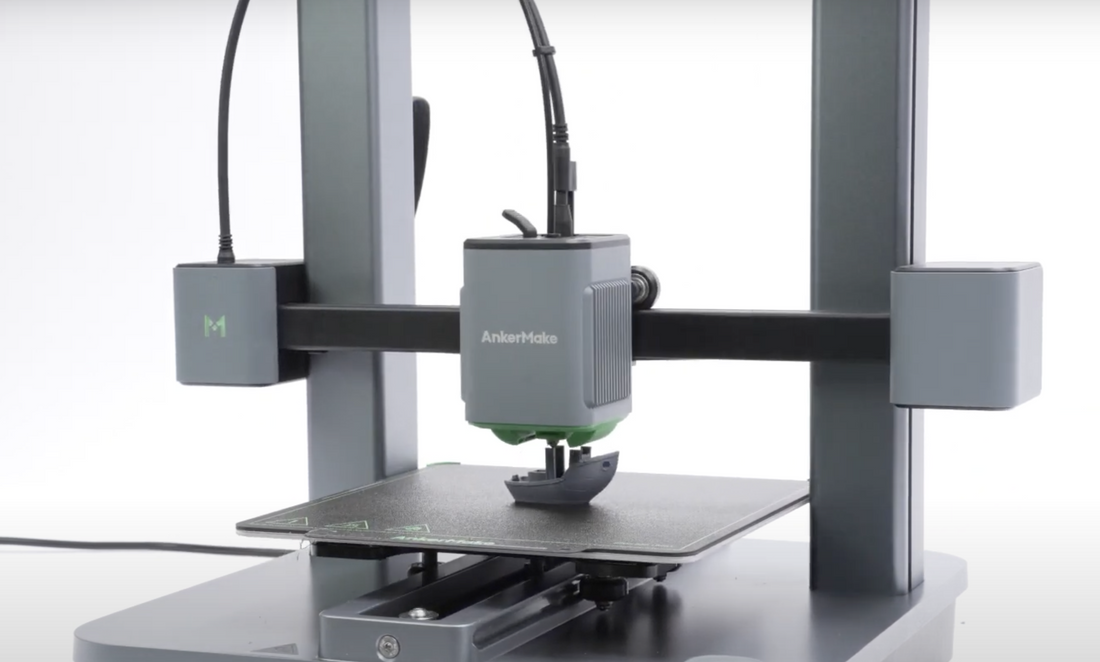

For example, the AnkerMake M5 3D printer moves its nozzle up to 500mm/s, finishes layers quickly, and has a strong build plate to keep prints stable. Upgrading the cooling fan (to keep plastic from melting too much) also lets you print faster.

{{ component: "product", handle: "m5", sku: "V81111C1"}}

Finding the Right Balance

Faster printing always means trade-offs. Thick layers or big nozzles make things quicker but less smooth. Test changes on small projects first—like a cube or a simple tool—to see what works best.

Quick Answers to Common Questions

Why does my print take so long?

Complex designs, slow settings, or an older printer all slow things down. Simplify your model, raise the speed, or consider a faster machine.

What is the best print speed for PLA?

For PLA printing, optimal print speed can depend on the model size, 3D printer, and specific settings. Generally, a speed of 40 mm/s to 60mm/s is suitable for PLA. If you want to speed up PLA printing, you can try the following methods:

- Use nozzles with larger size

- Choose a low infill percentage

- Reduce thickness of each layer

What’s the Best Infill for Speed?

Grid or Triangular patterns at 10–20% density work well for most fast prints.