What is the Strongest 3D Printer Filament?

Share

Finding the right filament is crucial for creating durable, functional 3D prints. Different materials excel in specific strength categories, and understanding these differences helps you select the optimal filament for your application.

This guide looks at what makes filaments "strong" and how to maximize your prints' durability.

Key Takeaways

- Polycarbonate is the strongest 3D printer filament for most applications.

- Nylon is the strongest filament in terms of tensile strength.

- TPU is the strongest flexible filament, ideal for parts that need to bend without breaking

- Carbon fiber composites have the best rigidity and shape stability

What Does Strength Mean for 3D Printer Filament?

Strength in 3D printing isn't one-dimensional. A filament's suitability depends on four factors:

Tensile Strength measures how much pulling force a material can withstand before breaking, shown in PSI (pounds per square inch). Higher tensile strength creates prints that resist stretching and pulling forces.

Impact Resistance determines how well a material absorbs sudden forces without cracking or breaking. This property is essential for parts that might be dropped or struck during use.

Flexibility allows materials to bend without breaking. While seemingly opposite to strength, this property is crucial for parts that need to flex repeatedly without failing.

Heat Resistance helps printed parts maintain their mechanical properties at high temperatures, preventing deformation under heat exposure.

What's the Strongest 3D Printer Filament?

Polycarbonate (PC)

Polycarbonate has great tensile strength of 4,060 to 10,900 PSI and excellent impact resistance. It keeps its shape at temperatures up to 150°C, making it great for high-stress parts

PC filament works well for making working prototypes that need real stress testing. When used for car mounting brackets, it's very tough, though it needs careful printing.

Best For: Working prototypes, safety equipment, high-heat uses

Challenges: Needs high printing temperatures (260-310°C), soaks up moisture, and tends to warp without a heated box. Good prints need dry filament and an enclosed printer to keep steady temps.

Nylon

Nylon has the highest tensile strength among common filaments, ranging from 7,250 to 13,100 PSI, along with excellent wear resistance and natural slickness. It mixes flexibility and toughness to make parts that don't break under stress.

For moving parts, nylon works best. Gears printed with nylon last much longer than other materials due to less friction and better fatigue resistance.

Best For: Moving parts, gears, tools, hinges, machine parts

Challenges: Quickly soaks up moisture, needs high printing temps (220-270°C), and tends to warp. Keep nylon in sealed boxes with drying packets and dry it just before printing.

PETG

PETG has become popular for mixing decent strength (6,500 PSI) with easy printing. It sits between easy-to-print PLA and tough ABS.

PETG is stronger than PLA for impact resistance and durability. When comparing ABS vs PETG, PETG has better tensile strength, while ABS handles higher heat better.

Compared to ASA, PETG has better impact strength but ASA resists sun damage and heat better.

Best For: Working parts, water-proof items, machine parts, food-safe uses (with proper rating)

Challenges: Tends to string, can stick too much to print beds, and soaks up moisture. Print with good cooling, use proper bed prep, and keep it dry.

TPU (Thermoplastic Polyurethane)

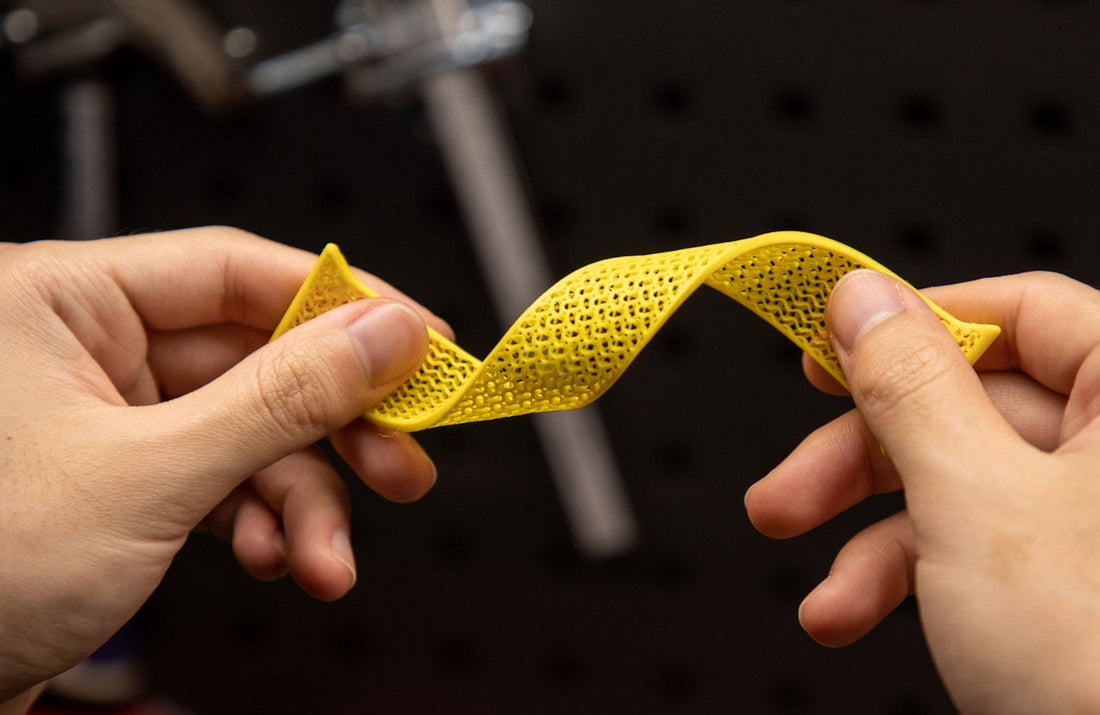

TPU is the strongest bendy filament for 3D printing. While it has lower tensile strength than stiff filaments, its mix of flex and toughness makes it almost unbreakable for some uses. TPU parts can bend many times without breaking.

Best For: Flexible parts, cases, shock absorbers, wearables

Challenges: Hard to print with Bowden extruders due to flexibility, needs slower print speeds (30-40mm/s), and can string. Direct-drive extruders work best for clean TPU prints.

PLA and PLA+

PLA is the most popular filament in 3D printing, primarily due to its environmental friendliness and ease of use. It is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane.

While not the strongest filament for 3D printer as compared to the first four on the list, PLA has good tensile strength (around 5,787 to 7,614 PSI) and is easy to print. It makes clean, exact parts with great surface quality.

PLA+ is a better version with improved impact resistance and slightly better heat handling than standard PLA.

Best For: Prototypes, display models, simple tools, and low-stress indoor items

Challenges: Low heat resistance (softens around 60°C), brittle when hit, and breaks down in sunlight. PLA parts often warp in hot cars, making them bad for outdoor or hot uses.

At eufyMake, we take pride in offering PLA 3D printer filaments that not only meet but exceed the standard expectations of strength and reliability.

Our PLA filaments, optimized for high-speed printing, have been rigorously tested in our Speed Lab for over 12 months. These extensive tests have showcased the filaments' resilience and durability, characteristics essential for high-strength 3D printing. Featuring a minimal shrinkage rate of just 0.33%, our filaments ensure precise and consistent printing, addressing common challenges like brittleness that often compromise filament strength.

{{ component: "product", handle: "pla-filament", sku: "V6110221"}}

Carbon Fiber Composites

Carbon fiber filaments mix a base material (usually PLA, PETG, or nylon) with chopped carbon fibers. These mixes are stiffer, hold their shape better, and weigh less than plain versions.

Carbon fiber filaments are stronger than their base materials for stiffness and resist bending. Carbon fiber nylon is very strong, mixing nylon's high tensile strength with carbon fiber's stiffness.

Best For: Stiff frame parts, items needing exact dimensions, lightweight uses

Challenges: Wears down nozzles, more brittle than base materials, and costs more. Use hardened steel or ruby nozzles to prevent early nozzle wear.

How to Improve the Strength of 3D Prints

You can make your 3D prints stronger by increasing wall thickness, adding more infill, and adjusting layer height. If you print parts in a way that reduces stress along layer lines, they’ll hold up better under pressure.

What’s more, post-processing methods like annealing can add extra strength.

There are even more ways to enhance durability—check out our full guide for details.

Warp it Up

Picking the strongest filament means knowing what your project needs and what strength types each material offers.

Nylon has the highest tensile strength, polycarbonate gives the best impact resistance, TPU is best for flex with durability, and PEEK handles the highest heat.

For most working mechanical parts, polycarbonate offers the best mix of strength properties, though it's harder to print than materials like PETG. By matching the right filament to your use and tuning your print settings, you can make 3D printed parts that rival factory-made parts in strength and durability.

FAQ

Here are some commonly asked questions about the strongest 3D printer filament.

Which is stronger? PLA, Nylon or PETG?

Nylon is the strongest of these three materials in terms of tensile strength and durability. PETG has better overall strength than PLA with moderate tensile strength, better impact resistance, and good chemical resistance. While PLA has decent tensile strength it's more brittle and less heat-resistant than the others, making it functionally weaker for most applications.

Is PLA stronger than TPU?

PLA is stronger than TPU when it comes to tensile strength, meaning it can withstand more force without stretching or breaking. This makes PLA more rigid and better suited for structural parts that need to hold their shape. However, TPU outperforms PLA in terms of durability and abrasion resistance, making it more suitable for objects that need to withstand wear & tear.

Can strong filaments be used on any 3D printer?

Not all 3D printers are compatible with strong filaments like Polycarbonate or Nylon. The ability to use these materials depends on the printer's extruder temperature range, bed temperature capabilities, and mechanical design. Always check your printer's specifications or manufacturer's guidelines to confirm compatibility before using these robust materials.