PLA Print Speed: Best Settings for Quality 3D Prints

Share

In the world of 3D printing, we often pursue greater speed so we can print our models faster without losing quality in our final result. But what is speed, and when printing PLA, what speeds can we achieve?

What Does 3D Printer Speed Mean?

Print speed refers to how fast the motion system of a 3D printer moves while printing. It is not just one number, though;

It is made up of several components. These include wall speed, infill speed, top/bottom surface speed, retraction speed, and travel speed.

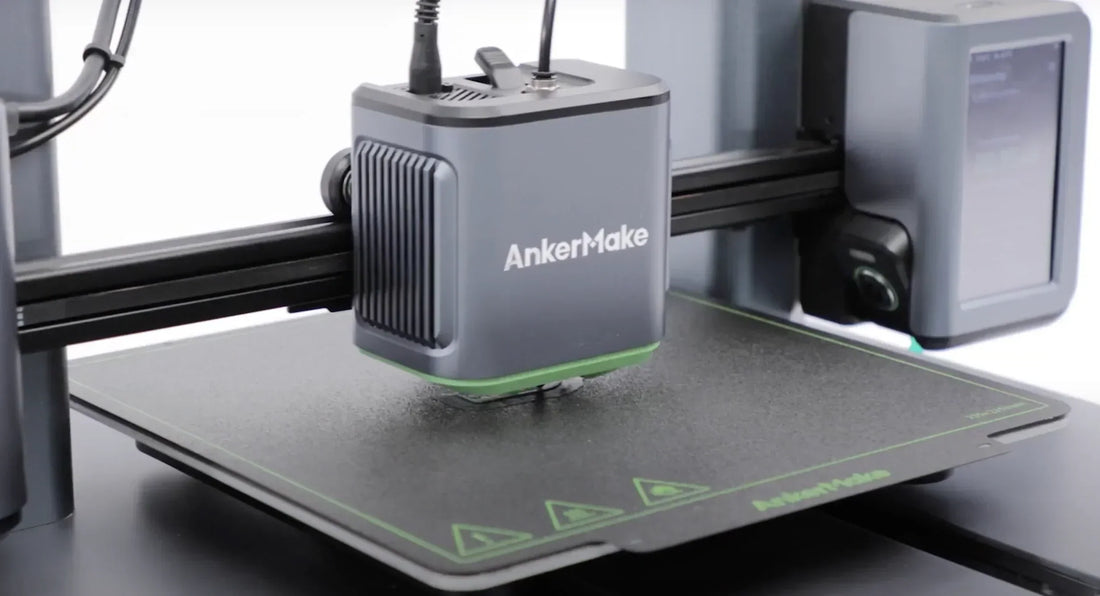

Speed is typically measured in millimeters per second (mm/s). Although Ankermake printers can easily achieve print speeds of up to 500mm/s in some cases, you may need to dial that back to achieve the results you desire.

Wall Speed

Controls the speed of outer and inner walls. The AnkerMake default is 250 mm/s (150 mm/s for external walls), but slowing it down improves surface quality.

Infill Speed

Determines how fast internal structures are printed. The AnkerMake default is 250 mm/s, but 80-150 mm/s is common for standard PLA.

Top/Bottom Surface Speed

Affects smoothness of the top and bottom layers. The AnkerMake default is 150 mm/s, but 30-50 mm/s is ideal for a better finish.

Retraction Speed

Controls how quickly filament is pulled back to prevent stringing. The default is 60 mm/s, but some filaments may need adjustments.

Travel Speed

Governs how fast the print head moves between sections. The AnkerMake default is 250 mm/s to reduce print time.

Different types of PLA filament print best at different speeds and can also have different surface finishes when printed slower or faster. Keep reading to find out how this varies between PLA types.

How Does Print Speed Affect Your Print?

Before considering different PLA types, we first need to examine how increasing speed might affect your prints.

At higher print speeds (250 mm/s+), you may start to notice issues with the quality of your prints, such as ringing, ghosting, or under-extrusion. This is why the default external wall speed is set to 150 mm/s to ensure a good surface finish on most prints.

One aspect of your prints that could be affected-but may not be initially noticeable-is layer adhesion. When the print head is moving at greater speeds, each layer of filament may not correctly adhere to the prior layers, leading to weakened parts that may fail to print or be easier to break. This is especially prevalent in Silk filaments.

Another consideration at higher print speeds is the need for increased part cooling.

To achieve high-quality PLA prints, we use part cooling fans to produce impressive overhangs. Without proper cooling, the filament can droop and cause print issues. Therefore, if the print head is moving faster, the part cooling capacity will need to be increased to harden the filament quickly enough.

What is a Good 3D Printing Speed?

A key consideration when deciding on the printing speed is the balance between speed and quality. Higher speeds can significantly reduce print times, which is beneficial for large-scale productions or simpler models. However, for prints that require fine details or have complex geometries, a slower speed is preferable to ensure accuracy and precision.

Best Speed Settings for Different Types of PLA Filament

Most PLA filaments print well using AnkerMake Studio's default speeds, which are designed for high-speed, efficient printing. However, if you experience issues such as poor layer adhesion, dull surfaces on Silk PLA, or excessive stringing, slight speed adjustments may be needed to improve results without sacrificing print time significantly.

If layer adhesion is weak, especially with Matte PLA or Silk PLA, reducing the wall speed to 100-150 mm/s (instead of the default 250 mm/s) can improve bonding. Infill speeds of 120-180 mm/s strike a balance between print speed and structural strength, preventing brittle prints. Matte PLA, which tends to be more fragile, can also benefit from lowering top/bottom surface speeds to 80-100 mm/s for smoother, more even layers.

For Silk PLA, if prints appear dull rather than glossy, the default speeds may be too high for proper layer fusion. Reducing the wall speed to 80-120 mm/s and top/bottom surface speed to 60-80 mm/s allows layers to blend more smoothly, enhancing the filament's natural shine. Lowering retraction speed to 40-50 mm/s can also help prevent stringing, which is common with Silk PLA.

PLA+ and High-Speed PLA can handle faster printing better than standard PLA, but if stringing or inconsistent extrusion occurs, adjusting retraction speed to 50-60 mm/s or reducing infill speeds to 150-200 mm/s ensures smoother, more controlled filament flow. If high-speed printing leads to rough top surfaces, lowering top/bottom speeds to 100-120 mm/s can improve the final finish.

If you notice surface imperfections such as ringing or rough textures, reducing the top/bottom speeds to 80-100 mm/s (instead of the default 150 mm/s) helps smooth out the finish, particularly for Matte and Silk PLA.

Tips for Optimizing Print Speed Without Sacrificing Quality

-

Use the right temperature: Higher speeds require higher nozzle temperatures to maintain flow. It is always suggested that you run a temperature tower test at your desired print settings to find each filament's optimal print temperature.

-

Adjust cooling settings: Faster prints need stronger cooling fans, especially for Silk PLA. Try some overhang tests with different levels of part cooling, checking for drooping while ensuring proper layer adhesion.

-

Perform test prints: Running calibration tests such as the flow rate test and VFA test in AnkerMake Studio will help you find the limits of what is possible with any given filament, allowing you to tune your settings just below that limit for optimal results.

-

Check acceleration & jerk settings: High-Speed PLA benefits from higher acceleration values, as it often has a lower viscosity when at temperature. If acceleration is set too low, it can lead to oozing on print travel moves.

If your prints aren't turning out as you expect, here is a quick lookup table of suggested speeds you could try for different types of filament.

Suggested Speed Adjustments for Different PLA Types

|

Filament Type |

Wall Speed (mm/s) |

Infill Speed (mm/s) |

Top/Bottom Speed (mm/s) |

Retraction Speed (mm/s) |

Travel Speed (mm/s) |

|

Standard PLA |

150-200 for details |

120-180 for better strength |

80-100 for a smoother finish |

25-40 if stringing occurs |

120-200 for accuracy |

|

Matte PLA |

100-150 for stronger adhesion |

100-150 to avoid brittle prints |

80-100 for even layers |

20-30 to prevent oozing |

100-150 to reduce vibrations |

|

Silk PLA |

80-120 for smooth surface |

100-150 for better flow |

60-80 for a shinier surface |

40-50 for silk properties |

100-150 to avoid shaking |

|

PLA+ (Enhanced PLA) |

150-200 for durability |

150-200 for strength |

100-120 for better surface quality |

50-60 for better control |

150-200 for smoother movements |

Final Thoughts

Finding the right 3D printer speed for your PLA prints is key to getting quality results. Remember, it's not just about printing fast-the right balance of wall, infill, top/bottom, retraction, and travel speeds can make all the difference. Experiment with different settings, test your prints, and adjust your cooling and temperature as needed.

With a bit of trial and error, you'll discover the perfect speed for your printer and filament. Happy printing!

FAQ

Here are some commonly asked queries about 3D printer speed.

Is it better to 3D print fast or slow?

The choice between fast or slow printing depends on your specific needs and the capabilities of your 3D printer. Fast printing is suitable for simpler designs and quick prototypes but may compromise on quality and detail. Slow printing, while more time-consuming, ensures higher accuracy, better detail, and stronger structural integrity, making it ideal for complex and detailed models.

What happens if you 3D print too fast?

If you 3D print too fast, it might lead to several potential problems. The most common issue is poor layer adhesion, where the layers do not have enough time to bind together, leading to structural weakness. In some cases, the print layers might shift, causing a distorted print. Over-extrusion, heat creeps, and various other hardware issues can also occur due to printing too quickly.

Are more expensive 3D printers faster?

Generally, yes. More expensive 3D printers often offer faster printing speeds. They typically come with advanced features like better precision, higher quality components, and more sophisticated software that can contribute to faster and superior overall performance. However, the speed at which a 3D printer operates often depends on various factors, not just the cost. Factors like the complexity of the print job, the type of material used, and the printer's design, all influence the operational speed of a 3D printer.