What Materials Do 3D Printers Use?

Share

3D printing is a fantastic technology that lets us create all sorts of objects from digital designs. It's like having your own mini-factory at home! However, there are many materials to choose from, and they can be tricky to understand. To get the best results, it's important to choose the right material for your project.

In this guide, we'll explore the common materials used in 3D printing and focus more on FDM 3D printing, which is the type of 3D printing that most people can easily access and use.

Common 3D Printing Materials for FDM

1. PLA (Polylactic Acid)

PLA is a biodegradable plastic made from plants, which is good for the environment. It's easy to print with, produces little smell, and gives good size accuracy with a smooth surface.

However, it's not the best choice for objects that will be exposed to heat, as it can start to deform at around 50°C. Also, PLA can become brittle over time.

Generally, PLA is a versatile material that works well for a wide range of projects. You can use it for prototypes, decorations, models, household items, and more.

2. ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong and tough plastic that can withstand a lot of wear and tear. It's better than PLA when it comes to heat resistance, so it's often used for car parts, tools, and other objects that need to be durable.

The downside is that ABS can be a bit tricky to print with because it likes to warp and curl up at the edges. It also gives off a noticeable smell during printing, so make sure you have good ventilation!

3. PETG (Polyethylene Terephthalate Glycol)

PETG is like a mix between PLA and ABS. It's almost as easy to print with as PLA but has the strength and durability of ABS. PETG is a good choice for objects that need to be strong, flexible, and resistant to chemicals. It's often used for things like water bottles, mechanical parts, and food containers. Compared to PLA and ABS, PETG offers a nice balance between easy printing and good performance. If you want to know more, we've got a guide all about the differences between PETG and PLA.

4. TPU (Thermoplastic Polyurethane)

TPU is a flexible and rubbery material that can bend and stretch without breaking. It's great for objects that need to be flexible and durable, like phone cases, watch bands, and toys.

TPU is also good at resisting chemicals and can be printed on most FDM 3D printers. Just keep in mind that it can be a bit stringy during printing, so you might need to adjust your settings.

5. Nylon

Nylon is a strong and tough plastic that can withstand a lot of wear and tear. It's often used for things like gears, bearings, and parts that need to be both strong and flexible.

Nylon can be a bit challenging to print with because it likes to absorb moisture from the air, which can cause problems with warping and poor layer adhesion. It also needs to be printed at a high temperature, so make sure your 3D printer can handle it.

6. Polycarbonate (PC)

Polycarbonate is a very strong and impact-resistant plastic that's often used for car headlights, safety glasses, and bullet-proof windows. In 3D printing, it's used for objects that need to be really tough and can withstand high temperatures. However, printing with PC can be quite difficult because it requires high temperatures and a special enclosed chamber to prevent warping.

Special Materials for FDM

1. Carbon Fiber Filaments

Carbon fiber filaments are made by mixing a regular plastic, like PLA or Nylon, with tiny carbon fiber strands. This makes the material much stronger and stiffer than regular plastic. Carbon fiber filaments are great for printing lightweight and durable parts for drones, robots, and other high-performance applications.

2. Wood Filaments

Wood filaments are a mix of PLA and real wood fibers, so you can print objects that look and feel like they're made of wood. These filaments are popular for making decorations, toys, and furniture prototypes. However, they can be a bit more challenging to print with because they need to be printed at lower temperatures and can sometimes clog up the nozzle.

3. Metal Filaments

Metal filaments are made by mixing PLA or ABS with fine metal powders, like copper, bronze, or stainless steel. While you can't print solid metal parts with these filaments, you can create objects that have a metal-like appearance and are a bit heavier than regular plastic. Metal filaments are often used for making jewelry, figurines, and cosplay props. Just keep in mind that they can wear down regular brass nozzles, so you might need to use a harder nozzle made of stainless steel.

4. Conductive Filaments

Conductive filaments are special materials that can conduct electricity. They're made by mixing plastic with conductive particles like carbon or graphene. These filaments are used for printing circuits, sensors, and other electronic components. However, they're not as conductive as regular metal wires, so they might not work for all electronic projects.

Other Types of 3D Printing Materials

1. Resin (SLA/DLP)

Resin 3D printing uses liquid plastic that hardens when exposed to UV light. This type of printing is great for creating objects with very fine details and smooth surfaces, like jewelry, dental models, and miniature figures. However, resin prints can be a bit brittle and not as strong as FDM prints.

2. Powder (SLS/SLM)

Powder-based 3D printing uses a laser to melt or sinter thin layers of plastic or metal powder. This method is often used for industrial and engineering applications because it can create strong, complex parts without the need for support structures. However, powder-based 3D printing is usually more expensive and less accessible than FDM.

3. Ceramics

Ceramic 3D printing materials are used to create objects that can withstand very high temperatures and are resistant to chemicals. They're often used for making dental and medical implants, high-temperature parts, and artistic sculptures. However, ceramic prints can be brittle and usually require additional processing steps after printing, like firing in a kiln.

What is the Best Material for 3D Printing Beginners?

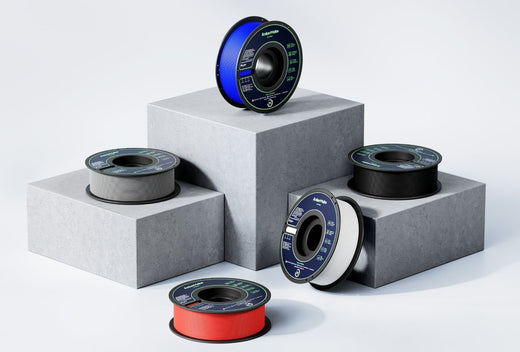

If you're new to 3D printing, PLA is the ideal material to start with. As what we mentioned above, it's easy to print, produces minimal odor, and doesn't require a heated bed. PLA also comes in a variety of colors and finishes, making it perfect for creating fun and unique objects. For a high-quality option, you can try AnkerMake PLA Filament.

The Future of 3D Printing Materials

1. Eco-Friendly Materials

As people become more aware of environmental issues, there's a growing demand for 3D printing materials that are biodegradable and made from sustainable resources. Scientists and companies are working on developing new filaments made from things like algae, coffee waste, and plant-based materials.

2. Composite Materials

Composite materials are made by combining different materials to create a new material with improved properties. In 3D printing, this could mean mixing plastics with carbon fiber, glass fiber, or metal powders to create stronger, lighter, or more heat-resistant parts. These advanced materials are especially useful for aerospace, automotive, and sports equipment applications.

3. High-Performance Polymers

High-performance polymers are special plastics that have excellent mechanical, thermal, and chemical properties. Some examples include PEEK, ULTEM, and PEKK. These materials are often used in aerospace, automotive, and medical industries for parts that need to withstand extreme conditions. As 3D printing technologies improve, we might see more of these high-performance polymers being used in consumer-level 3D printers.

4. Smart Materials

Smart materials, also known as responsive materials, are an exciting new area in 3D printing. These materials can change their shape, color, or other properties in response to things like heat, light, or electricity. For example, you could print an object that changes shape when you heat it up or a color-changing accessory that responds to sunlight. As research in this field progresses, we might see more 3D printed objects that can adapt and interact with their environment.

Conclusion

As you can see, there's a wide range of 3D printing materials, each with its own pros and cons. Whether you're a beginner making your first 3D print or an experienced maker tackling more advanced projects, understanding the properties of different materials is key to getting the best results. As 3D printing technology continues to advance, we can expect even more innovative materials that expand the possibilities of what you can create.

So dive in, experiment, and explore the exciting world of 3D printing!

FAQs about 3D Printing Material

What's the most popular 3D printing material?

PLA is the most widely used 3D printing material, especially for beginners. It's easy to print with, biodegradable, and comes in many different colors and finishes.

What's the best material for high-temperature applications?

Polycarbonate (PC) and PEEK are two of the best materials for high-temperature 3D printing. They can withstand temperatures well above 100°C (212°F) without deforming or losing strength.

Are there any materials that can't be 3D printed?

Some materials are very difficult or impossible to 3D print with current technologies. These include certain metals with very high melting points, like tungsten and titanium alloys, and some types of glass and thermoset plastics that can't be melted and re-solidified.