3D Printing Cost Calculator: Top 8 Picks

Share

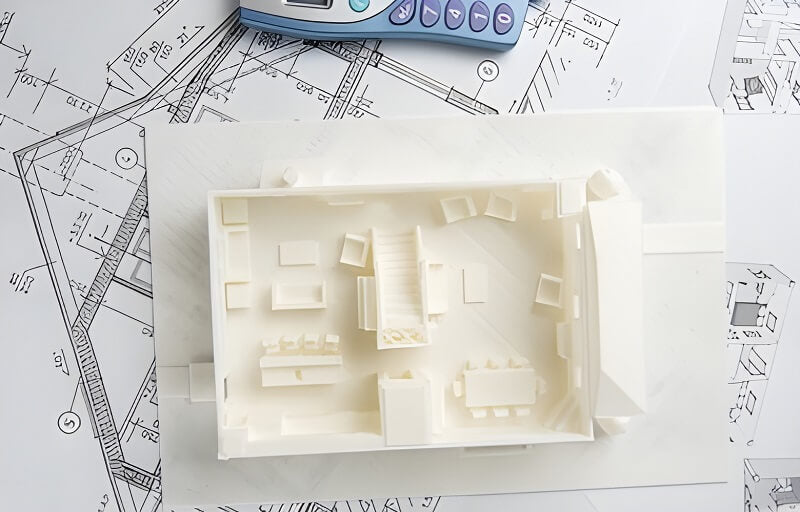

3D printing technology is gradually finding extensive applications in healthcare, automotive, and construction due to its freedom from geometric constraints. However, since 3D printing falls under additive manufacturing, it can be quite expensive. So, it's crucial to consider costs carefully for every 3D printing project.

If you also face challenges in 3D printing cost estimates, you might want to explore the 3D printing cost calculators. These tools can help you plan your budget effectively and estimate potential costs before starting your 3D printing project. In this case, today's post will introduce 8 practical and powerful 3D printing cost calculators to you. Now without further ado, let's dive in!

Best 3D Print Cost Calculator

The widespread adoption of 3D printing has given rise to numerous 3D print price calculators. Among them, some focus on user-friendly interfaces, while others offer advanced options for professionals, ensuring accurate insights. If you're unsure about how to choose, in this section, we will recommend the top 8 3D printing cost calculators. You can compare them to find the one that best suits your project's needs.

1. Prusa Calculator

Prusa Calculator is a professional and free program. It offers web and software versions for your convenience, allowing you to choose the appropriate tool based on your usage scenario. It primarily focuses on calculating energy costs, labor costs, and machine maintenance expenses. Meanwhile, due to its elaborate design, you can not only use it to calculate the total cost of filament based on filament type and filament failure rates, but also directly add other possible cost data, like Kapton tape, glue sticks, nozzle, and more to calculate the overall cost of 3D printing.

2. Omni Calculator

Omni Calculator is a free and comprehensive calculator online, with the 3D printing cost calculator being one of them. Its user-friendly interface has three main sections: material cost, labor cost, and the final price. Recognizing that calculation units may vary depending on different regions and projects, this calculator provides multiple units for each value. Additionally, it provides detailed explanations of 3D printing calculations, allowing manual verification of results.

3. Fabbaloo

Fabbaloo is ideal for users who own 3D printers as it factors in the printer's purchase price in the cost calculation. This online 3D printing price cost calculator tool emphasizes energy consumption, operational time, and equipment lifespan. If you're a 3D printing service provider or produce and sell 3D printed products, this calculator can aid in pricing and service provision. Besides, clear instructions for each input field make it user-friendly and efficient

4. IC3D's Job Cost Calculator

If you're looking for a simple but detail-oriented 3D print cost calculator, you can give IC3D's Job Cost Calculator a try. It is also an online tool and free to use. Visit the tool's webpage, you'll notice that it pays particular attention to filament cost in the calculator. You can calculate the cost of 3D printing filament cost by selecting filament density, size, and the time required for printing. While IC3D offers such a straightforward calculation service, the precision in cost details within 3D printing makes it worth a try.

5. MakerShop's 3D Print Cost Calculator

In addition to the basic calculation of material and energy costs, MakerShop's 3D Print Cost Calculator also covers some details such as machine wear, maintenance, bed adhesion, and 3D print markup percentage. Since this 3D printing cost calculator is web-based, it has pre-set calculation units for your convenience, allowing you to fine-tune the numerical options to obtain the desired cost results. Better still, this 3D print cost calculator supports STL files. It can break down your file and provide estimated values necessary for calculating the printing cost.

6. Xometry's 3D Printing Cost Calculator

Xometry is a provider of 3D printing services, and its website offers a handy 3D printing price cost calculation tool. Unlike other calculators that manually input or select options, Xometry's 3D Printing Cost Calculator allows you to directly upload data files for cost estimation. This 3D printing service cost calculator supports various file formats such as STEP, STP, SLDPRT, STL, DXF, and more. If you already have existing 3D printing cost data files, this tool is worth a try.

7. Shatter Box

Shatter Box is free software, which can be used to calculate 3D printing costs even without an internet connection. Like other 3D print price calculators, Shatter Box calculates material, labor, energy, and other costs by adjusting parameters. However, it boasts a standout feature in its ability to provide multiple profiles for different printers. For 3D printing businesses that use various 3D printers, this feature not only can save time but also store the cost data of each 3D printer.

8. 3D Print HQ

Print HQ comes with a simple interface and offers both web and software versions for your convenience, allowing you to switch between them as needed. With pre-set units, you only need to select the corresponding values to obtain the 3D printing cost results. What's even better is that the software supports exporting a 3D printing cost calculator spreadsheet (Excel file). The clear tabular data greatly facilitates subsequent printing tasks.

How Does 3D Print Pricing Calculator Work?

A 3D printing pricing calculator estimates the total cost of a 3D printing project by analyzing multiple factors. Here's a breakdown of how it functions:

Material Costs

Material expenses are calculated based on the type and quantity required for a project. For example, PLA and ABS filaments typically cost $20-$30 per kilogram, while specialty resins, often used in resin printing cost calculators, can range from $50 to over $150 per liter. The calculator determines the material usage by analyzing the volume of the 3D model, infill density, and support structures, often measured in grams or milliliters.

Printer Operating Costs

Operating costs include electricity and wear on the printer. Are 3D printers costly to run? To accurately calculate the 3D printer electricity cost entered in the calculator, consider the printer's power consumption (in watts) and your local electricity rate. In this way, you can get 3D printing cost per hour. For example, A standard FDM printer consuming 100 watts per hour and running for 10 hours adds approximately $1.20 (at $0.12/kWh). Wear and tear, such as nozzle replacements ($10-$20) or build plate upkeep, are amortized across multiple prints and factored into the cost.

Labor Costs

Labor costs cover all the hands-on work involved, like setting up the printer, keeping an eye on the process, and handling post-print tasks. These costs can change depending on how skilled the operator is and how tricky the project is.

Print Time

When using a commercial 3D printer, the cost of printing time is often included in the overall pricing. How much should you charge for 3D print time? For example, a business that invests $2,000 in a 3D printer with a lifespan of 2,000 hours may set its hourly printing rate at approximately $1 to recover the machine's cost over its operational life.

For personal printers, this factor is usually excluded since individuals don't typically calculate the hourly cost of their own equipment for personal projects. This is especially true when using a budget-friendly yet high-performing printer like the AnkerMake M5 3D Printer. With its fast printing speeds of up to 500 mm/s and advanced features like AI-powered monitoring and 7×7 auto-leveling, the M5 not only reduces print time but also ensures precision and quality.

Post-Processing

Post-processing includes all the finishing touches, like taking off supports, sanding rough edges, curing resin, or painting. SLA prints, for example, often need extra steps like cleaning the resin and curing it with UV light, which can add $5-$20 per print. SLS or multi-material prints using advanced techniques will drive up the cost even more.

Wrap It Up

Using a 3D printing price calculator is a practical way to manage costs and optimize your printing process. The calculators highlighted in this article offer a variety of features-some provide detailed, all-encompassing cost analyses, while others focus on specific aspects of printing expenses. With such a range of options available, choosing the calculator that best suits your needs will ensure accurate cost estimation and a more streamlined printing experience.

FAQ

How much does it cost to 3D print per inch?

The 3D printing cost per cubic inch varies based on the material and method. Resin prints using SLA or DLP range from $0.70 to $3 per gram, while metal prints cost between $10 to $100 per cubic centimeter. The exact costs per inch would depend on material density and design specifics.

What is the average cost to 3D print?

The average cost to 3D print varies based on material, printer type, and project size. A basic PLA print may cost $0.10-$0.50 per gram, including electricity and filament. More complex prints, like resin or metal, can cost $50-$500, depending on the material, post-processing, and labor.

Is 3D printing profitable?

3D printing can be profitable, especially for custom, high-value items like prototypes, personalized products, or small-batch manufacturing. Profitability depends on managing costs (materials, labor, electricity) and market demand.

How do you calculate the cost of a 3D model?

To calculate the cost of a 3D model, you are recommended to use a 3D printing cost calculator. And here are the specific steps below.

- Identify the material type and its price per kg and density.

- Use modeling software to calculate model volume.

- Multiply the volume by material density for the model's mass.

- Multiply the mass by material price.

- Add other expenses, such as labor, electricity, and any post-processing requirements.